For applications with high variations in temperature

perma NOVA can be used for applications that are within a temperature range of -20°C up to +60°C. A discharge period of 1 to 12 months can be easily programmed by pushing the selection button on the NOVA control unit. A temperature sensor regularly measures the ambient temperature and the control unit calculates the required gas generation based on this data. This ensures a continuous and controlled discharge. perma NOVA consists of a reusable control unit, a lubricant canister and a light weight protection cover.

Applications

perma NOVA is a single point lubricator* especially well suited to the lubrication of bearings on equipment where there is considerable variation in ambient temperature or where intrinsic safety is required, such is often the case in the oil and gas industries. The re-usable control unit contains a temperature sensor which allows the behaviour of the lubricator to automatically adjust to the operating conditions. The perma NOVA is IP65 rated meaning that it is dust tight and protected against water jets.

* Also commonly referred to as an autolube, permalube or automatic lubrication system

Maschinenelemente

Product characteristics

Elektronische Steuereinheit mit Temperaturkompensation zeigt Spendezeit / Betriebszustand

Electronic control unit with temperature compensation shows discharge period / operating status

LCD display and push button, Setting: 1, 2, 3, ...12 months & LC size

- Reusable NOVA Control unit

- Temperature independent during the entire discharge period

- Accelerated pressure built-up for first discharge within one day

- Simple handling / easy adjustments

System arbeitet zuverlässig bei -20 °C bis +60 °C

System works reliably from -20 °C to +60 °C

- Ideal for applications with considerable temperature variations

- One system for subfreezing as well as high temperature applications

- Integrated support flange for stronger connections

Ex-Schutz-Zulassung IP 65

Ex-proof certification

IP 65

- Safe and reliable lubrication in explosive areas

- Increased workplace safety

- Dust-tight and protected against water jets

Technical Data

- Drive

- Electrochemical reaction via gas generating cell, Electronic temperature compensation

- Housing

- Transparent plastics

- Discharge period

- 1, 2, 3, …, 12 months

- Lubricant volume

- 65 cm³, 125 cm³

- Operating temperature

- -20 °C to +60 °C

- Pressure build-up

- max. 6 bar

- Number of outlets

- 1

- Protection class

- IP 65

- Lubricants

- Grease up to NLGI2 /oil

- Max. tube lengths

- 2.00 m

- CE

- Ex

- IEC Ex

INSTALLATION KITS

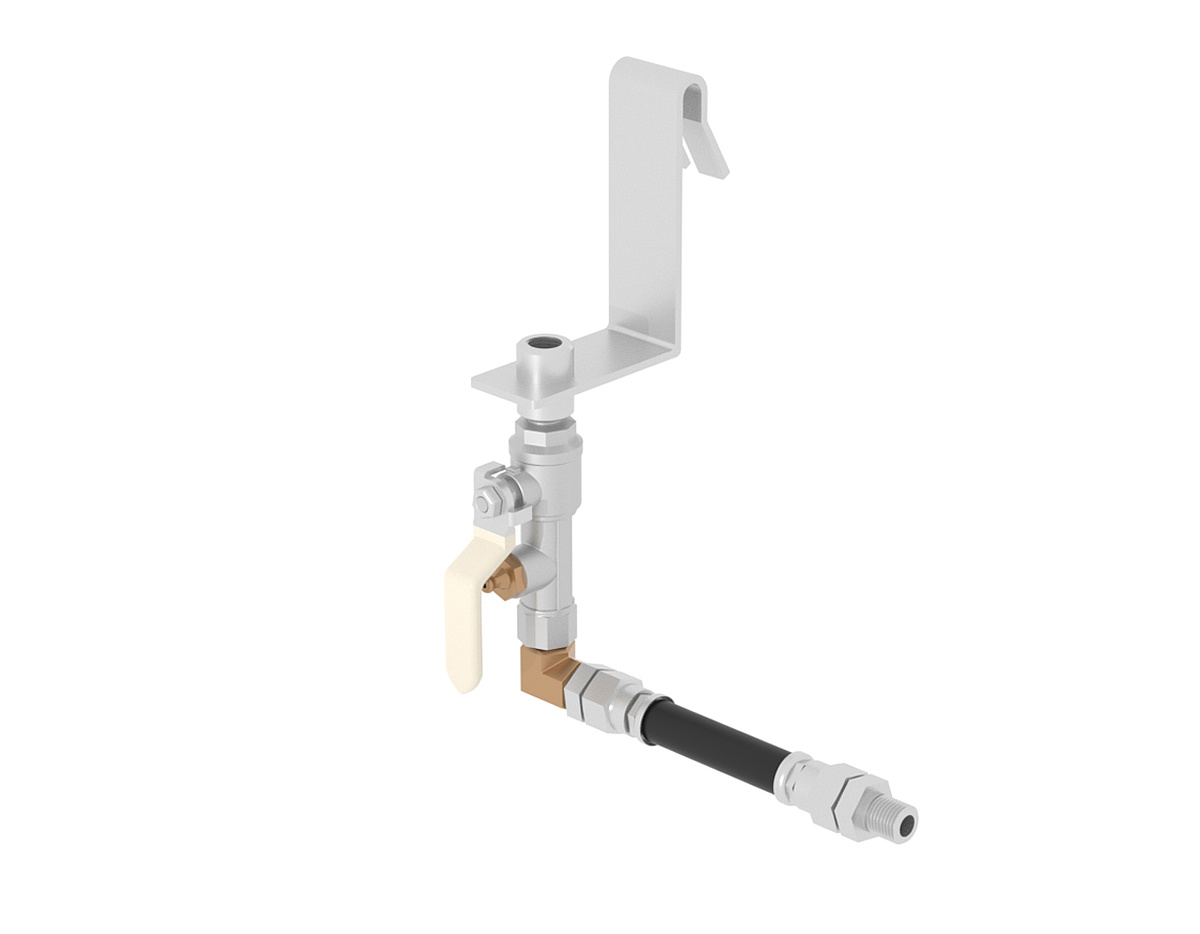

Installation kit (part no. K130G)

Contents 1 x 1 point bracket 2 x 30mm SS beam clamp 1 x Manual purge kit 2 x Female swivel hose ends 1 x 90 deg elbow 1 x 1/4” BSPF – 1/8” BSPM reducer 1 x 1/4" BSPF – 1/8” BSPM extension 1.0 mtr of 3/8" ID grease line

Installation kit (part no. K2CHG)

Contents 1 x 2 point cage bracket 2 x Manual purge kit 2.0 mtr of 3/8” ID grease line 4 x Female swivel hose ends 2 x 90 deg elbow 2 x 1/4” BSPF – 1/8” BSPM reducer 2 x 1/4" BSPF – 1/8” BSPM extension

Installation kit (part no. K1CHS)

Contents 1 x 1 point cage bracket 1 x Manual purge kit 1.0 mtr of 3/8” ID grease line 2 x Female swivel hose ends 1 x 90 deg elbow 1 x 1/4” BSPF – 1/8” BSPM reducer 1 x 1/4" BSPF – 1/8” BSPM extension

Installation kit (part no. K230G)

Contents 1 x 2 point bracket 2 x 30mm SS beam clamp 2 x Manual purge kit 4 x Female swivel hose ends 2 x 90 deg elbow 2 x 1/4” BSPF – 1/8” BSPM reducer 2 x 1/4" BSPF – 1/8” BSPM extension 2.0 mtrs of 3/8" ID grease line